Introduction

DW_EndLineTest is an application for testing dish washing machines at the end of the production line. This application is based to the DW DEA 601 timer.

Installation

Before installing DW_EndLineTest, it need to install SNPM (Simple Network Management Protocol) as Windows component (Control Panel, Applications Installation, Windows Components, Management tools).

To install the application launch the Setup_DW_EndLineTest.exe executable file, and choose all required components during setup.

Configuration

First configure IP address of place's Phoenix device. From “Run…”, launch regedit, find HKEY_LOCAL_MACHINE\SOFTWARE\Phoenix Contact\IBSETH\Parameters\1 key and setup the following items:

InUse = Yes

IPAddress = Phoenix IP address (example: 192.168.0.1).

To edit DW_EndLineTest configuration open with a text editor the DW_EndLineTest.exe.config file (in Bin directory).

<?xml version="1.0" encoding="utf-8" ?> <configuration> <appSettings> <add key="LINGUA" value="it"></add> .... <add key="PLC_IP" value="127.0.0.1"></add> <add key="PLC_PORT" value="5000"></add> <add key="CVM_PORT_NUMBER" value="2"></add> .... <add key="DW_PORT_NUMBER" value="1"></add> .... <add key="DRAGON_PORT_NUMBER" value="3"></add> <add key="LVS_DURATA_SCARICO" value="15"></add> </appSettings> </configuration>

LINGUA

Language of the application. Available values: it for italian, pl for polish.

PLC_IP

IP Address of the computer, to receive communications from Cassioli PLC.

PLC_PORT

Network TCP communication port between PC and Cassioli PLC. Default: 5000 + place number.

CVM_PORT_NUMBER

Serial port number of the CVM device. Default value: 1.

DW_PORT_NUMBER

Serial port number of the DW machine bridge. Default: 2.

DRAGON_PORT_NUMBER

Serial port number of the Dragon barcode scanner. Default: 3.

LVS_DURATA_SCARICO

Dishwasher machine drain phase duration in seconds, in case of negative test.

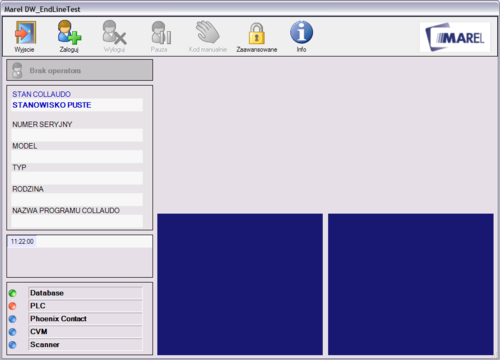

Main window

Toolbar

Tool bar contains buttons to access to main functions of application (for example: user's login and logout, advanced tools).

Left panel

Left panel shows user name (if present), place status (EMPTY, PRODUCT PRESENT, ELECTRIC TEST, TEST, END TEST, EMERGENCY), and data of current DW machine (serial number, model, description and process).

In the middle box there is the current time and the last system message.

In the lower box there is the communication status with database server, Cassioli PLC, Phoenix Contact device, CVM device and barcode scanner.

| Led | State |

|---|---|

| Ok |

| Communication error |

| Device disabled in configuration |

Test panel

This panel, divided in two parts, contains all informations about the current running test. In the upper part, it shows the name of the current command and its timeout (if present), and all its controls with the read value for each one. In the lower part, it prompts questions to the user.

Advanced

To unlock advanced tools, digit ”123” in the password window.

Processes

With this editor you can create and manage test processes. In the left listview, there are all present processes. To create a new process, right click with the mouse and choose Nuovo.

To rename a process, right click and choose Rinomina. To delete a process, right click and choose Elimina. To copy a process, right click and choose Copia.

To export a process, choose Esporta. To import a process from another factory, choose Importa.

Commands

Once you selected a process, you can edit its content with the middle panels, which are two commands groups executed simultaneously. To add a command, drag & drop it from the right upper panel to the desired group.

For each command it's necessary to select the test type:

- OR: Positive command result require at least one positive control test result.

- AND: Positive command result require all positive control test results.

Duration (timeout) of command execution is indicated in milliseconds.

Sistema_Attesa

This command wait for a predefined number of milliseconds before to execute its controls.

Sistema_Nullo

This command executes directly its controls.

Sistema_Elettrovalvola_Aria

This command is used to open and close air EV.

Sistema_Elettrovalvola_Acqua

This command is used to open and close water EV.

==

For a description of DW specific commands, read the EDT reference documentation.

Controls

Controls have some fixed parameters, and other variable parameters based on control type.

- Messaggio riparatore: This is the message reported to the repairman, if this control has negative result.

- Log: If checked, control result will be saved also with positive result.

- Tipo test (Test type):

- Nessuno: No test in the control.

- Errore senza interruzione: If control has negative result, test continues but with negative result.

- Errore con interruzione: If control has negative result, test breaks immediately with negative result.

- Variabile: Name of the variable where to save the control result, to use it later.

Prodotto_Conversione_Contalitri

This control converts the liter count of the DW machine from deciliters to liters, to compare it with the system liter count.

Prodotto_Conversione_Temperatura

This control converts the internal temperature of the DW machine in °C.

Sistema_Tensione

This control gives the read voltage (V) from the CVM device.

Sistema_Corrente

This control gives the read current (A) from the CVM device.

Sistema_Potenza

This control gives the read power (W) from the CMV device.

Sistema_Sfasamento

This control gives the read phase from the CVM device.

Sistema_Resistenza

This control gives the read resistance (Ohm) from the CVM device.

Sistema_Contalitri

This control gives the read liter count from the system.

Sistema_Portata

This control gives the flow meter (liters/minute) from two liter count readings.

Sistema_Temperatura_Acqua

This control gives the temperature (°C) of the water from the draining pump.

Sistema_Temperatura_Ambiente

This control gives the temperature (°C) of the ambient.

Funzione_Somma

This control sums values of two variables and checks result.

Funzione_Sottrazione

This control subtracts a value of a variable from a value of another variable and checks result.

Funzione_Moltiplicazione

This control multiplies the values of two variables and checks result.

Funzione_Divisione

This control divides the value of a variable with the value of another variable and checks result.

Funzione_Maggiore

This control has positive result if a value of a variable is greater than another.

Funzione_Minore

This control has positive result if a value of a variable is lower than another.

Funzione_Tra

This control has positive result if a value of a variable is between two assigned values.

Operatore_Tasto

This control shows a question to the user with two possible answers, one for positive result and one for negative result.

Operatore_Messaggio

This control shows only a message to the user.

Operatore_Difetto_Visivo

Same as Operatore_Tasto, but if the user set negative answer, it shows a new window where choose a visive defect.

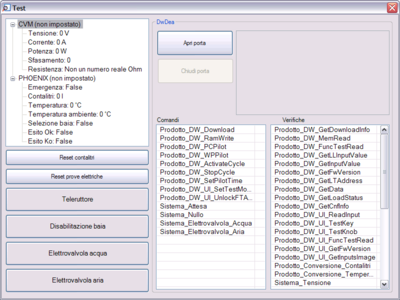

Test

This powerful test tool to make system debug or a wide product test. In the left list view, it shows real time values of CVM and Phoenix devices. At the bottom left there are some buttons to manage Phoenix device:

- Liter count reset

- Electric test reset

- Power switch

- Disable place

- Water EV

- Air EV

On the right panel it's possible to open communication with DW DEA 601 timer. All commands and controls are available. It need to read DW machine barcode before to open communication, to select the proper setting file. If you don't read barcode, applications shows the models window to choose the appropriate model.